Different Types of Metals

Technological and metal progression in the manufacturing process offered humans the industrial revolution. This spurred an unprecedented evolution of human civilization, taking us to where we are now. Today there are different types of metals all around us. They can be categorized in many ways, relying on what characteristic or property you utilize as a criterion. The simplest way of categorizing them is their iron capacity, atomic structure, and interaction with magnets.

When choosing metal for a specific use, there are quite a couple of factors to contemplate to find the most appropriate choice. These factors include melting point, cost, ease of machining, sufficient safety factor, space available, temperature coefficient, thermal and electrical conductivity, density, etc.

With over 3500 different grades and almost 2 billion tons of steel manufactured each year globally, the most commonly used metal globally turns out to be steel. Without further ado, let’s dig deeper into the world of carbon steel vs stainless steel!

Steel

Steel is one of the contemporary world’s most crucial materials for engineering and building. Its astounding versatility and durability make it helpful in anything from homes to industrial buildings to commercial machinery. You’ll discover it almost wherever you look and in numerous different sectors.

It’s a carbon-enriched iron alloy that’s normally devoid of the impurities and residues that come with iron. While iron is harder than other minerals, it is also very strong, impermeable, and corrosion-prone. Strictly iron structures can be tricky to maintain and build on these grounds. Adding carbon to iron mitigates these vulnerabilities, but it also makes the material stronger. Furthermore, steel has a rather high strength-to-weight ratio compared to other categories of metals, which allows the manufacturing of tiny yet solid steel parts.

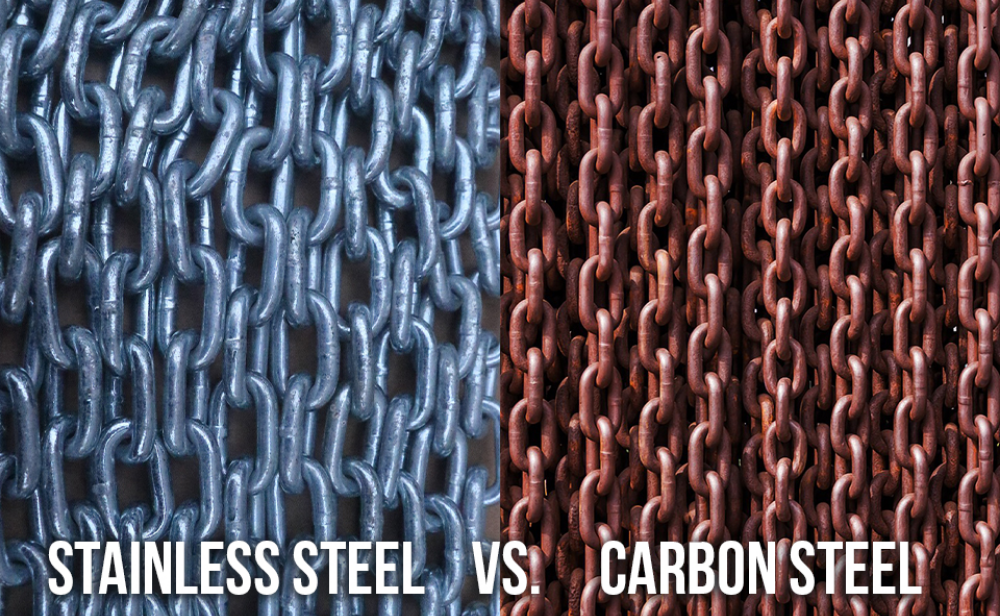

Many of us seldom consider all the differences in steel products. The two most common types are carbon Steel vs stainless steel, and they have several unique characteristics. Ensuring you’re acquiring the correct material for your application, it’s crucial to recognize the similarities and dissimilarities between the two types of metals.

Stainless Steel

Stainless steel, often known as inox steel (meaning inoxidizable from the French term inoxydable), lives true to its name by having a great resistance to corrosion stains. The mystical ingredients for stainless steel are chromium, nickel, and molybdenum. Stainless steel should contain at least 10.5 percent chromium by mass, whereas the content is usually much greater. Many stainless steel variants also incorporate some amounts of nickel and molybdenum to give extra enviable properties.

Stainless steel is the material used for food production equipment and utensils, medical devices, automotive parts, and much more. The most crucial characteristic is that stainless steel never rusts or oxidizes as other steel and iron products do.

Corrosion resistance, aesthetic appeal, low maintenance, and strength make stainless steel a popular choice for a variety of applications. You’re surrounded by panels manufactured from a shiny metal material wherever you visit a commercial kitchen or an infirmary. That’s stainless steel.

Stainless steel is also ecologically inert and neutral, and its lifespan guarantees it meets the requirements of sustainable construction. Its durability fulfills sustainable construction standards, and effective erection, installation, and low maintenance ensure the user an unmatched service life.

Carbon Steel

The term “carbon steel” usually means any steel whose main components are iron and carbon. The carbon component of these steels can range from 0.05 percent (in “mild” or low-carbon steels) to three percent (in ultra-high-carbon steels). There are three subgroups to this one: low, medium, and high carbon steel.

Low carbon steel: Up to 0.25% of carbon in iron gives us low carbon steel, also known as mild steel. Bolstering bars and I-beams in construction are normally from low carbon steel. Any use that requires a high proportion of steel without much bending or forming is also appropriate for it.

Medium carbon steel: It contains 0.2- 0.6% of carbon. Medium carbon steel’s applications include ones that need high tensile strength and ductility. They find use in steel beams in buildings and bridges, gearing and shafts, railway wheels and rails, etc.

High carbon steel: Steel that incorporates more than 0.6% of carbon is high carbon steel. This steel is tougher and more breakable than the previous two. It can be used in making chisels and cutting tools. Beneficial qualities include good resistance and hardness to material wear.

High carbon steels are really hard, making them great at countering abrasion and maintaining shape. They can resist significant force before deformation. Regrettably, hard metals are also breakable: high carbon steels are more prone to crack than bend when put under intense tensile stress.

Carbon steel vs stainless steel is a good-looking material with the smooth look usually associated with steel. It will also take several finishes and coatings, offering various cosmetic options for various environments. However, most carbon steels don’t have the shine and luster compared to other types of metals.

Carbon Steel Vs Stainless Steel

Carbon steel and stainless steel are dissimilar, but one is not inevitably better than the other. It’s all about the context of use. Each metal has pros and cons—the important part is matching the steel to the job prerequisite.

In terms of cost, stainless steel costs more than mild- or medium-carbon steel. However, very high-carbon steel can be more expensive compared to stainless steel. Since many factors in play ascertain how much you’ll compensate for steel, the finest method is usually to determine the particular performance factors you’ll desire and then look into both types of metal and how much they’ll cost.

Conclusion

So, if you are considering buying steel, take the time to narrow the ideal characteristics between carbon steel and stainless steel to make the right choice for your project. You will be grateful for doing this now rather than discovering out you chose the wrong one afterward.