There are a variety of ways to recycle the gold. High-value recycled gold makes up 90 percent of the global supply and is used in high-end jewelry. Other types of gold items are often recycled, including coins and bars. To learn more about the recycling process for gold, keep reading! There are many benefits to the process, and you’ll be glad you learned about it! After all, it’s better for the environment, too!

High-Value Gold Recycling

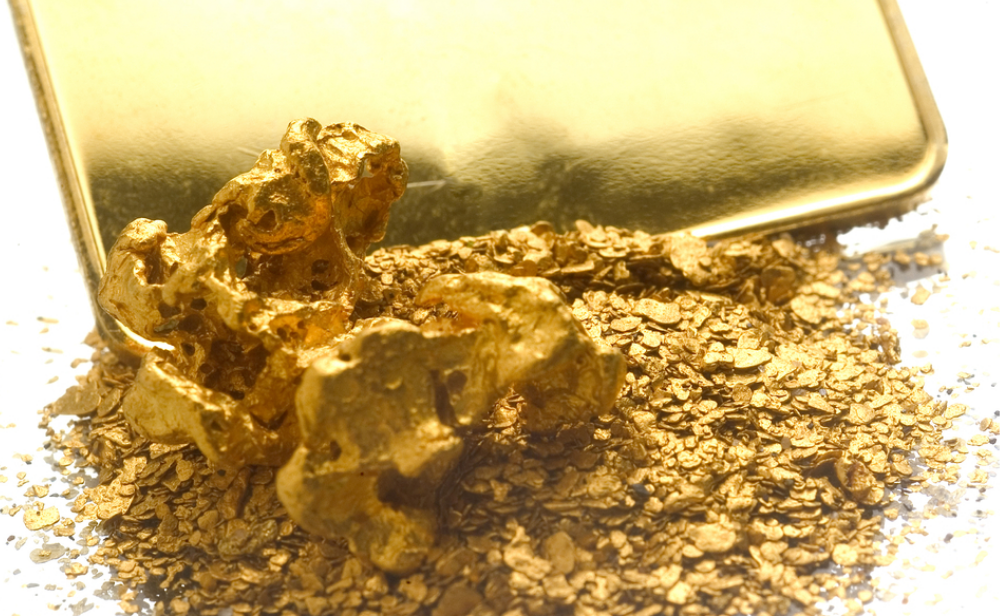

Industrial gold recycling is an emerging market that is gaining market share in the recycling sector due to government regulations. As of 2013, China alone is responsible for more than 90 percent of the global recycled gold supply, with the United States contributing only six percent. Industrial recycling includes gold bars, rounds, and numismatic coins. It also involves the type of gold alloy and purity, and the process for recovering high-value recycled gold must consider these factors.

Several methods for recovering gold from industrial waste, ranging from physical separation to chemical stripping. A significant proportion of gold may be mixed with other metals for high-value source materials. In some cases, it may be impossible to separate the metals through chemical stripping or mechanical separation, and further purification is required. Depending on the nature of the metal alloy, the process may be carried out by a jeweler or refiner without using specialist equipment.

The process of recovering high-value gold from low-value scraps is not as simple as it may seem. Some gold recycling firms have sophisticated separation processes to separate the two metals. Others separate them using melting and heating. Special jewelers may have the equipment to do this as well. However, to achieve higher purity levels, the processes at gold refineries are often more complex. The GaBi database does not reflect these complexities.

Refining of Precious Metals

Refining precious metals are important because it can separate them from other noble metalliferous materials. Noble metals can be used for various purposes, such as electronic assemblies, catalysts, and jewelry. A few sources that can be refined for precious metals are dental scrap, jewelry, electronics, and implants. However, if you’re looking for a company that will take your precious metal scraps, you should consider hiring a company that has been around for years.

Often, major refineries award recovery contracts based on processing fees. Others, like the United Nations, require that the lowest bidder wins. This approach fails to consider the real money involved in precious metals. Often, spent catalysts can contain valuable precious metals. If you’d like to know more about the process of refining precious metals, check out our Practical Guide to Assaying and Extracting.

The first step in the refining process is to test the catalyst for precious metals. Using a catalyst with an accurate analysis of the entire lot is essential. If the precious metal content is unknown, be wary of anyone who offers you payment for your catalyst. Always check quotes and contracts from prospective companies before deciding to purchase. You can even feed myths about the refining process with inaccurate samples!

Once the process is complete, the silver will be ready to be re-cast. Silver nitrate will then be fed back to the anode furnace. During this process, the impurities in the anode will build up in the electrolyte, which is why silver refining is so important. Many methods can refine gold, but one method remains the most common and efficient.

Recovering Gold From Electronic and Industrial Waste

A Canadian start-up called Excir is implementing a process that chemically extracts the metal to recover gold from electronic and industrial waste. The company claims it can recover 99 percent of the gold in e-waste. It has received $4.3 million in funding for its project. The Canadian firm has already begun using its process on a small scale and plans to expand it to mass production.

In the first stage of the process, NBS oxidizes gold on the surface of the CPU pins, forming a low concentration of bromoacetate. The oxidation byproduct AuBr3(py) stabilizes the gold. A leaching mixture is used to recover 90 percent of gold and other metals. This method is very cost-effective and enables the recycling of various materials.

The final recovery rate of gold was 99% in some cases. However, it was only 60 percent when considering the loss of gold due to grinding and shredding processes. This high recovery rate suggests that it is possible to prevent any loss of precious metals. In the future, microwave pyrolysis will replace grinding and shredding processes. Overall, the process yields about 93% gold, suggesting that approximately seven percent of the PCBs in waste are unsuitable for sequential recovery.

Life Cycle Assessment of Recycled Gold

The life cycle assessment of recycled gold includes several factors affecting its environmental impact. One factor is the amount of gold recovered in the recycling process, which most influences its environmental impact. The use of acids and energy is also a significant contributor to the overall environmental performance of the recycling process. A decrease in these parameters will decrease the global warming potential of recycled gold. Overall, recycling gold reduces the environmental impacts of the industry. However, it is important to note that these factors have a lot of variabilities.

The study assumes that the refineries examined are state-of-the-art facilities equipped with modern machinery and good process flows. This assumption is based on data from Germany, so different assumptions may be made in other countries. Another consideration is whether technology can increase transparency regarding the origin of recycled gold. Compared to waste-based recycling methods, monetary value is the best measure of recycled gold’s environmental impact. The study also considers the costs and benefits of renewable assets, such as gold, and the potential value of waste-water treatment facilities.

The most commonly used methods to assess the environmental impact of recycled gold include those that use it in jewelry. The process is less complex than WEEE recycling, and it is still important to understand the process. The goal is to decrease the environmental impact of gold recycling while decreasing an entity’s exposure to virgin gold. Gold recycling should be incorporated into all life cycle assessments to achieve this. It is important to note that different processes make the gold in recycled jewelry, but a common element is recycling high-value scrap.

Conclusion

Therefore, it is concluded that recycling gold is a great way to revamp old jewelry and other gold items that are unique or have sentimental value. These items have character, but they might be worn out or even broken. It’s always good to preserve the past, but it’s also great to use that past at the same time!. Gold is melted down for uses like creating new jewelry, thanks to the recycling process. Recycling is the best way to protect the environment, and it can help you make good money! The gold recycling process isn’t just a way to reuse gold. It’s also incredibly beneficial for you. Learn more about the process and what it can do for our world.